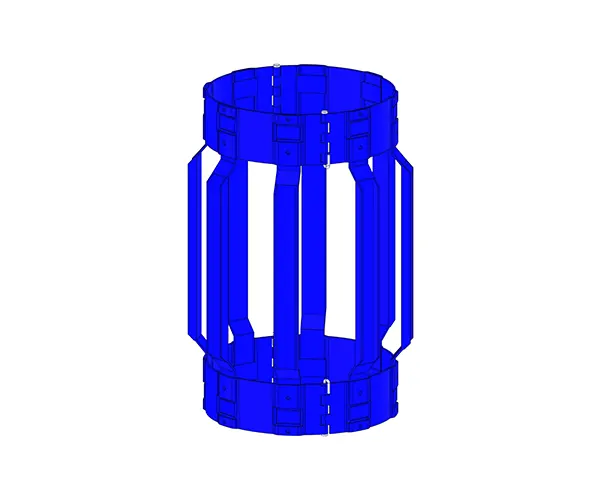

Float Collar

Float Collar

A vital component positioned near the bottom of the casing string during primary cementing operations is the float collar. This device serves as a landing point for cement plugs, facilitating the efficient sealing of the annular space between the casing and the wellbore.

Typically comprised of a short section of casing equipped with a check valve, the float collar is designed to prevent the unwanted flowback of cement slurry once pumping ceases. This check valve can be of various types, such as flapper-valve or spring-loaded ball valve assemblies, among others. Regardless of the design, the check valve’s function remains consistent: to inhibit the reverse flow of cement slurry into the casing.

The absence of a float collar poses significant risks during cementing operations. Without it, cement slurry placed in the annulus could experience a phenomenon known as U-tubing, where it reverses flow back into the casing. This occurs due to the higher density of cement slurries compared to the displacement mud inside the casing, creating a gravitational effect.

By effectively blocking reverse flow, the float collar ensures the integrity of the cement job by preventing U-tubing. This safeguards the wellbore against potential cementing failures and contributes to the overall success of the cementing operation.

Features

- Conventionl

- Self Locking or non roatating type

- Stab intype

- Stab in latch in Float Shoe

- Auto fill Float Shoe

- Differential fill up Float Shoe